Specification

Material: stainless steel

Model Number : 1/4''

Working principle: atmospheric pressure

Size:75*12.5mm

Working temperature: 0-200 ℃

Working pressure: 0.6bar-1.2bar

Injection angle: 30

Scope of application: dust belt transportation screening point of coal mine unloading point dust quarry

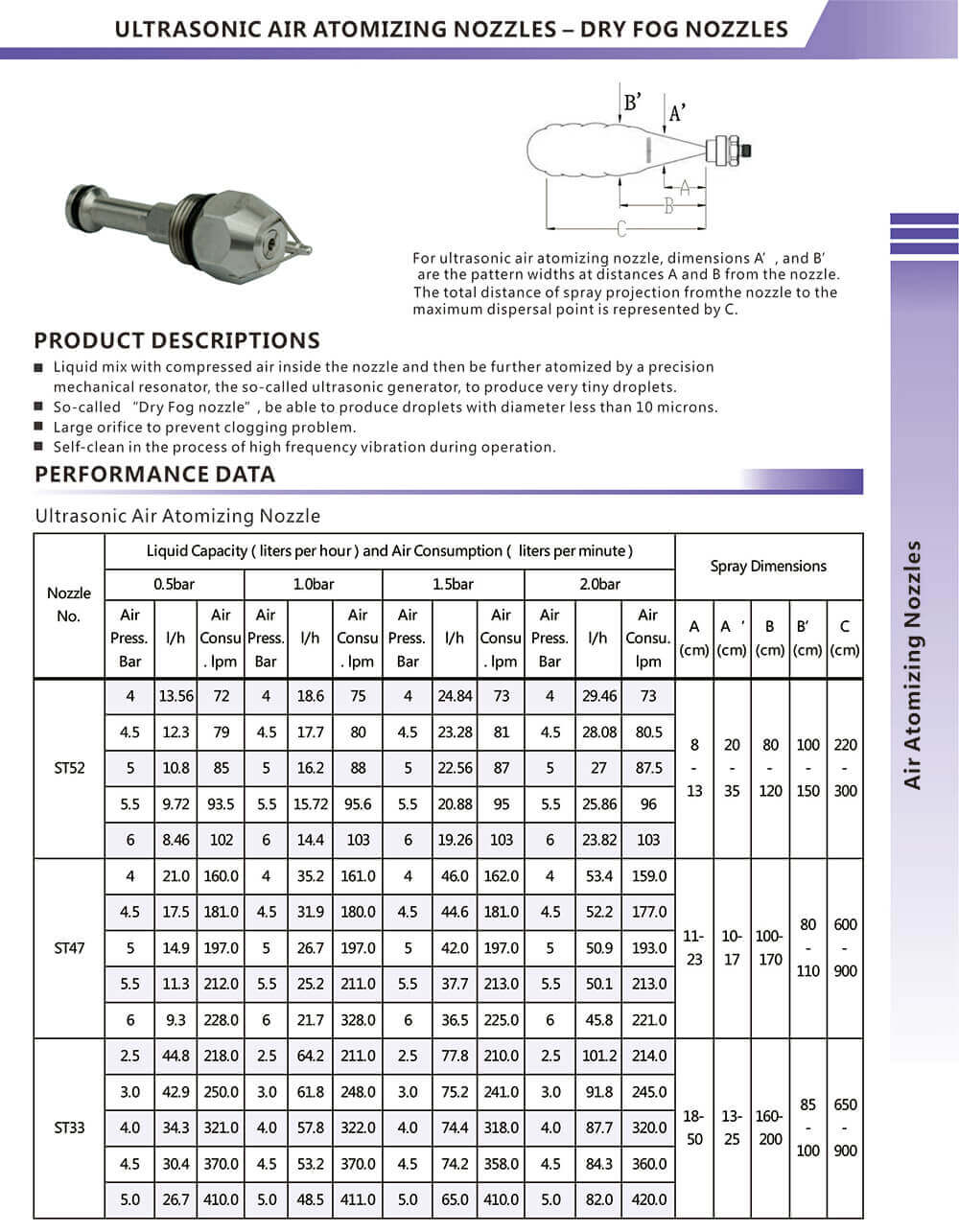

Ultrasonic air atomizing nozzle humidifying dust suppression dry fog nozzle

Stainless steel ultrasonic atomizing nozzle has the ability to produce very fine fog droplets, that is, the meaning of dry fog, ultrasonic atomizing nozzle droplets size of 1-10 microns. Ultrasonic atomizing nozzle uses the friction between compressed air and liquid to produce very uniform and the finest atomizing effect, the average diameter of atomized particles is less than 50 microns.

Specification

Material: stainless steel

Model Number : 1/4''

Working principle: atmospheric pressure

Size:75*12.5mm

Working temperature: 0-200 ℃

Working pressure: 0.6bar-1.2bar

Injection angle: 30

Scope of application: dust belt transportation screening point of coal mine unloading point dust quarry

|

Categories |

Spray Angle 80° |

SV882 Spray Angle 60° |

Spray Angle 30°

|

|

Gas pressure |

5.2bar |

3.5bar |

5.2bar |

|

Water pressure |

1.5bar |

0.6bar |

1.2bar |

|

Gas consumption |

115L/Min |

260L/Min |

240L/Min |

|

Water consumption |

7.1L/Hr |

45L/Hr |

20L/Hr |

|

Atomizing granularity |

3-6microns |

4-10microns |

7-10microns |

|

Gas filtration demand |

<40microns |

<40microns |

<40microns |

|

Water filtration demand |

<50microns |

<50microns |

<50microns |

Features

● Spray particles can be fine to about 10 microns;

● Ultrasonic waves are generated by mechanical resonance;

● The nozzle consists of the nozzle part and the base part;

● Does not rely on high pressure, water pressure is only 0.6 and 1.2bar;

● 100% stainless steel casting, eliminating wear and corrosion.

● Ultrasonic waves are generated by mechanical resonance;

● The nozzle consists of the nozzle part and the base part;

● Does not rely on high pressure, water pressure is only 0.6 and 1.2bar;

● 100% stainless steel casting, eliminating wear and corrosion.

.jpg)